Krohne H250 Metal Tube Rotameter

Basic Info

Model No.: H250

Product Description

Krohne H250 Metal Tube Rotameter Product Description 1. H250 Variable Area Flow Meter 1.1 Highlights • Simple, low-cost installation: Measure and display without auxiliary power supply • Rugged stainless steel construction for high operating pressure up to 3000 bar / 44100 psi and extreme process temperatures of -200...+400°C / -328...+752°F • Optionally available with PTFE/ceramic liner for acids and alkalis • High application safety, evenwith extremely low flows • Excellent long-term stability • Modular and flexible to adapt to customer-specific applications • SIL 2 certified • International approvals for use in hazardous areas and nuclear power plants 1.2 Industries Can be used in all industrial sectors, for example: • Chemicals • Petrochemicals • Pharmaceutical • Machinery • Food & Beverage • Oil & Gas • Iron, Steel & Metals • Power plants • Pulp & Paper • Water & Wastewater 1.3 Applications • Continuous gas and liquid measurement • Measurement of conductive and non-conductive media • Industrial burner controlling • Compressor monitoring • Dry-run protection of pumps 2. Options and variants 2.1Stainless steel indicator housing (H250/M9R)  For particularly rough environmental conditions, the M9 indicator housing is optionally available in stainless steel. This guarantees its reliable use in corrosive atmospheres caused by operational emmissions. When installed outdoors, external influences such as salt fog or contaminated precipitation no longer lead to corrosion.The stainless steel housing is equally well-suited for use in splash water zones such as in the food and luxury food industry. 2.2FOOD & PHARMA (H250 F)

For particularly rough environmental conditions, the M9 indicator housing is optionally available in stainless steel. This guarantees its reliable use in corrosive atmospheres caused by operational emmissions. When installed outdoors, external influences such as salt fog or contaminated precipitation no longer lead to corrosion.The stainless steel housing is equally well-suited for use in splash water zones such as in the food and luxury food industry. 2.2FOOD & PHARMA (H250 F)  The only EHEDG-certified variable area flowmeter approved for used in the food and pharmaceuticals industry.Smooth stainless steel surfaces with a surface roughness of ≤0.8 µm or 0.6 µm of the wetted parts make deposition difficult and are very easy to clean.Combined with a design featuring no dead spaces or stagnation zones, micro-organisms have no chance to adhere and multiply.The measuring devices can be cleaned (CIP) and sterilised (SIP) in place. Suitable connections and FDA conforming materials for the food and pharmaceutical industry are available. 2.3 PTFE/ceramic liner for aggressive media

The only EHEDG-certified variable area flowmeter approved for used in the food and pharmaceuticals industry.Smooth stainless steel surfaces with a surface roughness of ≤0.8 µm or 0.6 µm of the wetted parts make deposition difficult and are very easy to clean.Combined with a design featuring no dead spaces or stagnation zones, micro-organisms have no chance to adhere and multiply.The measuring devices can be cleaned (CIP) and sterilised (SIP) in place. Suitable connections and FDA conforming materials for the food and pharmaceutical industry are available. 2.3 PTFE/ceramic liner for aggressive media  All wetted parts are made ofPTFE or ceramic and can thus be used for almost all acids and alkalis. Depending on the choice ofmaterial, the measuring device can be used up toa maximum temperature of 70°C / 158°F (PTFE) or 250°C / 482°F (ceramic). 2.4Versions for special installation positions (H250H / H250U)

All wetted parts are made ofPTFE or ceramic and can thus be used for almost all acids and alkalis. Depending on the choice ofmaterial, the measuring device can be used up toa maximum temperature of 70°C / 158°F (PTFE) or 250°C / 482°F (ceramic). 2.4Versions for special installation positions (H250H / H250U)  Variable area flowmeters typically feature a vertically positioned measuring cone through which the medium flows from bottom to top, lifting a float against the weight. If the installation structure does not permit otherwise,versions for horizontal or inverted (from top to bottom) installation positions are used.The missing reset force of the variable area float weight is replaced by a spring. 3 Indicator variants 3.1 Indication M9 (modular)

Variable area flowmeters typically feature a vertically positioned measuring cone through which the medium flows from bottom to top, lifting a float against the weight. If the installation structure does not permit otherwise,versions for horizontal or inverted (from top to bottom) installation positions are used.The missing reset force of the variable area float weight is replaced by a spring. 3 Indicator variants 3.1 Indication M9 (modular)  • Local indication without auxiliary power supply• 2 limit switches (NAMUR or 3-wire transistor) • 2-wire current output 4…20 mA with HART ® • Profibus PA interface • 6-digit flow counter withpulse output (non Ex) • Intrinsically safe Ex i (ATEX, FM, NEPSI) 3.2 Indicator M10 (integrated)

• Local indication without auxiliary power supply• 2 limit switches (NAMUR or 3-wire transistor) • 2-wire current output 4…20 mA with HART ® • Profibus PA interface • 6-digit flow counter withpulse output (non Ex) • Intrinsically safe Ex i (ATEX, FM, NEPSI) 3.2 Indicator M10 (integrated)  • Graphic display for measured value and counter display • 2 limit switches (NAMUR or open collector transistor) • 2-wire current output 4…20 mA with HART ® • 12-digit flow counter with pulse output and reset input • Explosion proof enclosure Ex d (ATEX, FM, CSA, NEPSI) 3.3 Indicator M8 (compact)

• Graphic display for measured value and counter display • 2 limit switches (NAMUR or open collector transistor) • 2-wire current output 4…20 mA with HART ® • 12-digit flow counter with pulse output and reset input • Explosion proof enclosure Ex d (ATEX, FM, CSA, NEPSI) 3.3 Indicator M8 (compact)  • Compact, space saving design • Intrinsically safe Ex i (ATEX) M8M • Mechanical indicator without auxiliary power • 2 limit switches (NAMUR) M8E • Electronic bargraph indicator • 2-wire current output 4…20 mA with HART ® 4. Technical data • The following data is provided for general applications. If you require data that is more relevant to your specific application, please contact us or your local representative. • Additional information (certificates, special tools, software,...) and complete product documentation can be downloaded free of charge from the website (Download Center). 4.1Measuring system

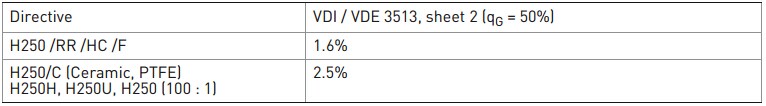

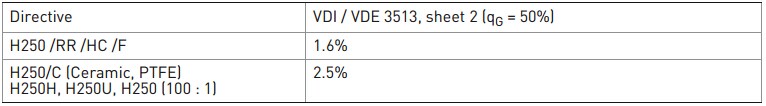

• Compact, space saving design • Intrinsically safe Ex i (ATEX) M8M • Mechanical indicator without auxiliary power • 2 limit switches (NAMUR) M8E • Electronic bargraph indicator • 2-wire current output 4…20 mA with HART ® 4. Technical data • The following data is provided for general applications. If you require data that is more relevant to your specific application, please contact us or your local representative. • Additional information (certificates, special tools, software,...) and complete product documentation can be downloaded free of charge from the website (Download Center). 4.1Measuring system  4.2 Measuring accuracy

4.2 Measuring accuracy  4.3 Operating conditions

4.3 Operating conditions  4.4 Materials 1CrNi steel 1.4571 on request, for clamp connection CrNi steel 1.4435 2TFM/PTFE liner (electrically non-conductive) H250/C - DN100 / 4" only PTFE H250/F: wetted surfaces Ra ≤0.8 μm, optional ≤0.6 μm Other options: • Special materials on request: e.g. SMO 254, titanium, 1.4435 • Float damping: ceramic or PEEK • Gasket for devices with female thread as insert: O-ring FPM / FKM Krohne H250 Variable Area Flow Meter

4.4 Materials 1CrNi steel 1.4571 on request, for clamp connection CrNi steel 1.4435 2TFM/PTFE liner (electrically non-conductive) H250/C - DN100 / 4" only PTFE H250/F: wetted surfaces Ra ≤0.8 μm, optional ≤0.6 μm Other options: • Special materials on request: e.g. SMO 254, titanium, 1.4435 • Float damping: ceramic or PEEK • Gasket for devices with female thread as insert: O-ring FPM / FKM Krohne H250 Variable Area Flow Meter  Payment&The Delivery

Payment&The Delivery  Company Information

Company Information

Contact Us

Contact Us  Contact us if you need more details on H250 Metal Tube Rotameter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about H250 Metal Tube Rotameter、H250 Metal Tube Rotameter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on H250 Metal Tube Rotameter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about H250 Metal Tube Rotameter、H250 Metal Tube Rotameter. If these products fail to match your need, please contact us and we would like to provide relevant information.

For particularly rough environmental conditions, the M9 indicator housing is optionally available in stainless steel. This guarantees its reliable use in corrosive atmospheres caused by operational emmissions. When installed outdoors, external influences such as salt fog or contaminated precipitation no longer lead to corrosion.The stainless steel housing is equally well-suited for use in splash water zones such as in the food and luxury food industry. 2.2FOOD & PHARMA (H250 F)

For particularly rough environmental conditions, the M9 indicator housing is optionally available in stainless steel. This guarantees its reliable use in corrosive atmospheres caused by operational emmissions. When installed outdoors, external influences such as salt fog or contaminated precipitation no longer lead to corrosion.The stainless steel housing is equally well-suited for use in splash water zones such as in the food and luxury food industry. 2.2FOOD & PHARMA (H250 F)  The only EHEDG-certified variable area flowmeter approved for used in the food and pharmaceuticals industry.Smooth stainless steel surfaces with a surface roughness of ≤0.8 µm or 0.6 µm of the wetted parts make deposition difficult and are very easy to clean.Combined with a design featuring no dead spaces or stagnation zones, micro-organisms have no chance to adhere and multiply.The measuring devices can be cleaned (CIP) and sterilised (SIP) in place. Suitable connections and FDA conforming materials for the food and pharmaceutical industry are available. 2.3 PTFE/ceramic liner for aggressive media

The only EHEDG-certified variable area flowmeter approved for used in the food and pharmaceuticals industry.Smooth stainless steel surfaces with a surface roughness of ≤0.8 µm or 0.6 µm of the wetted parts make deposition difficult and are very easy to clean.Combined with a design featuring no dead spaces or stagnation zones, micro-organisms have no chance to adhere and multiply.The measuring devices can be cleaned (CIP) and sterilised (SIP) in place. Suitable connections and FDA conforming materials for the food and pharmaceutical industry are available. 2.3 PTFE/ceramic liner for aggressive media  All wetted parts are made ofPTFE or ceramic and can thus be used for almost all acids and alkalis. Depending on the choice ofmaterial, the measuring device can be used up toa maximum temperature of 70°C / 158°F (PTFE) or 250°C / 482°F (ceramic). 2.4Versions for special installation positions (H250H / H250U)

All wetted parts are made ofPTFE or ceramic and can thus be used for almost all acids and alkalis. Depending on the choice ofmaterial, the measuring device can be used up toa maximum temperature of 70°C / 158°F (PTFE) or 250°C / 482°F (ceramic). 2.4Versions for special installation positions (H250H / H250U)  Variable area flowmeters typically feature a vertically positioned measuring cone through which the medium flows from bottom to top, lifting a float against the weight. If the installation structure does not permit otherwise,versions for horizontal or inverted (from top to bottom) installation positions are used.The missing reset force of the variable area float weight is replaced by a spring. 3 Indicator variants 3.1 Indication M9 (modular)

Variable area flowmeters typically feature a vertically positioned measuring cone through which the medium flows from bottom to top, lifting a float against the weight. If the installation structure does not permit otherwise,versions for horizontal or inverted (from top to bottom) installation positions are used.The missing reset force of the variable area float weight is replaced by a spring. 3 Indicator variants 3.1 Indication M9 (modular)  • Local indication without auxiliary power supply• 2 limit switches (NAMUR or 3-wire transistor) • 2-wire current output 4…20 mA with HART ® • Profibus PA interface • 6-digit flow counter withpulse output (non Ex) • Intrinsically safe Ex i (ATEX, FM, NEPSI) 3.2 Indicator M10 (integrated)

• Local indication without auxiliary power supply• 2 limit switches (NAMUR or 3-wire transistor) • 2-wire current output 4…20 mA with HART ® • Profibus PA interface • 6-digit flow counter withpulse output (non Ex) • Intrinsically safe Ex i (ATEX, FM, NEPSI) 3.2 Indicator M10 (integrated)  • Graphic display for measured value and counter display • 2 limit switches (NAMUR or open collector transistor) • 2-wire current output 4…20 mA with HART ® • 12-digit flow counter with pulse output and reset input • Explosion proof enclosure Ex d (ATEX, FM, CSA, NEPSI) 3.3 Indicator M8 (compact)

• Graphic display for measured value and counter display • 2 limit switches (NAMUR or open collector transistor) • 2-wire current output 4…20 mA with HART ® • 12-digit flow counter with pulse output and reset input • Explosion proof enclosure Ex d (ATEX, FM, CSA, NEPSI) 3.3 Indicator M8 (compact)  • Compact, space saving design • Intrinsically safe Ex i (ATEX) M8M • Mechanical indicator without auxiliary power • 2 limit switches (NAMUR) M8E • Electronic bargraph indicator • 2-wire current output 4…20 mA with HART ® 4. Technical data • The following data is provided for general applications. If you require data that is more relevant to your specific application, please contact us or your local representative. • Additional information (certificates, special tools, software,...) and complete product documentation can be downloaded free of charge from the website (Download Center). 4.1Measuring system

• Compact, space saving design • Intrinsically safe Ex i (ATEX) M8M • Mechanical indicator without auxiliary power • 2 limit switches (NAMUR) M8E • Electronic bargraph indicator • 2-wire current output 4…20 mA with HART ® 4. Technical data • The following data is provided for general applications. If you require data that is more relevant to your specific application, please contact us or your local representative. • Additional information (certificates, special tools, software,...) and complete product documentation can be downloaded free of charge from the website (Download Center). 4.1Measuring system  4.2 Measuring accuracy

4.2 Measuring accuracy  4.3 Operating conditions

4.3 Operating conditions  4.4 Materials 1CrNi steel 1.4571 on request, for clamp connection CrNi steel 1.4435 2TFM/PTFE liner (electrically non-conductive) H250/C - DN100 / 4" only PTFE H250/F: wetted surfaces Ra ≤0.8 μm, optional ≤0.6 μm Other options: • Special materials on request: e.g. SMO 254, titanium, 1.4435 • Float damping: ceramic or PEEK • Gasket for devices with female thread as insert: O-ring FPM / FKM Krohne H250 Variable Area Flow Meter

4.4 Materials 1CrNi steel 1.4571 on request, for clamp connection CrNi steel 1.4435 2TFM/PTFE liner (electrically non-conductive) H250/C - DN100 / 4" only PTFE H250/F: wetted surfaces Ra ≤0.8 μm, optional ≤0.6 μm Other options: • Special materials on request: e.g. SMO 254, titanium, 1.4435 • Float damping: ceramic or PEEK • Gasket for devices with female thread as insert: O-ring FPM / FKM Krohne H250 Variable Area Flow Meter  Payment&The Delivery

Payment&The Delivery  Company Information

Company Information

Contact Us

Contact Us  Contact us if you need more details on H250 Metal Tube Rotameter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about H250 Metal Tube Rotameter、H250 Metal Tube Rotameter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on H250 Metal Tube Rotameter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about H250 Metal Tube Rotameter、H250 Metal Tube Rotameter. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Krohne Flow Meter

Other Products

Hot Products

Tube Connector Hydraulic Adatpor (IC-90007)Brass Forged Angle Boiler Drain Valve (AV4047)OEM&ODM Quality Brass Casting Bibcock (AV2015)Brass Forged Bibcock with T Brass Handle (AV2021)OEM&ODM Quality Polishing Brass Forged Faucet (AV2053)Brass Angle Raditaor Valve (AV3058)Italycopper Producted Female Brass Ball Valve (AV10021)HT-50 Metal Tube Variable Area vegetable oil flow meterPWA- IV type residual chlorine analyzerLWGY Liquid turbine flow meter type factoryLDG Electro Magnetic flow meterfactory wholesale cheap high quality high precision liquid coriolis mass flow meterLWQ gas turbine natural gas flow meter(SBL target type) bitumen flow meterTUF-2000F fixed ultrasonic flow meters (clamp on)LUGB Vortex flow meters