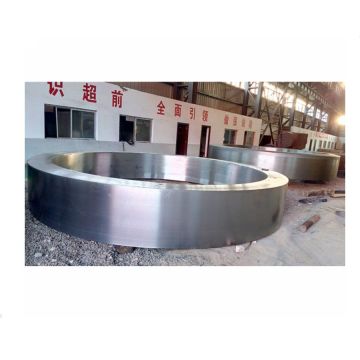

Stainless Steel Heated Forged Large Diameter Bearing Ring

Basic Info

Model No.: Customized

Product Description

Specifications

OEM precision forging steel ring

Forged steel ring Rough machining forging

FORGING THE FUTURE, WE DO THE BEST

OUR COMMITMENT: COMPETITIVE PRICE, HIGH QUALITY AND GOOD SEVICE

Company introduce

We established in 1984 year, named Zhangqiu Tongyong Machinery Company. In 2010 renamed Jinan Paiwo Engineering Machinery Co.,Ltd and established new plants. Covers an area of 66,000 Square meter, and has a building area of 14,000 Square meter. Currently, Paiwo has 100 employees, owns fixed assets reaching RMB 35 million, and boasts an annual output value of RMB 80 million and creates more than RMB 4 million taxes. So We have strong financial support.

We possess professional technical team, advanced equipment and detecting method, strict quality control system to meet all your customized requirements of forged ring. High quality, excellent performances and competitive price will make you rely on us and choose us.

Forging rings/forged rings/forging ring/forged ring/seamless rolled rings/seamless rolled ring/rolled rings/rolled ring/Contoured rolled rings/Contoured rolled ring/ Contoured seamless rolled ring/Contoured seamless rolled ring/Steel Rolled Rings/steel forging rings/steel forging ring/steel forged ring/steel forged rings/ring forging/ring forged/ring blank

Production Flow

- Raw Material Choose One-Level ingot steel, inspect chemical element , confirm achieve requirements.

- Forging Heating to the specified time and temperature. Have two kinds forging harmmer open forging and die forging .

- Heat Treatment According Tensile,Yield, Hardness requirements, fully heating. Incloud A,N,Q,T, surface HT and local HT.

- Machining Equip horizontal lathe, vertical lathe, CNC lathe, CNC machining center, turning machine,boring machine, milling machine, grinder. Tolerance can hold +/-0.02mm, surface roughness can hole Ra0.8. Grindering geometric tolerance.

- Inspect Every products mad a test bar, used for test hardness and mechanical properties. All forging rough 100% UT inspect.

Ablility

- We have qualified environmental impact assessment. So our production will not be affected by environmental inspection.

- We both have forging and machining ability.

- Two gas heating furnaces, monitored and controlled by computer programs to ensure precise heating within set time and temperature range as required.

- Including a 2500 Tons friction press, a 5 Tons hydraulic harmmer.

- A 3 axis CNC machining center, a milling planer, three CNC machining center, four milling center, three turning center, twenty CNC lathes. More than 80 workers.

- Value-added services such as, rolling, grindring, heat treatment, welding, hard chrome plating, polishing, painting, assembling are also avaliable.

- Regarding certification: BV,ISO9001-2008,TUV,PED.

- Three fields: Engineering machinery Hydraulic cylinder components, oilfield equipments components, Customized high precision spare parts.

- Dimensions range: φ50mm ~ φ1000mm Length: 150mm ~ 4000mm Weight: 20kg ~ 3 Ton

- Regarding range of material: Carbon steel, Cr&Mo Alloy steel, Stainless Steel

Quality Control:

1: On line inspection, we perform 100% on line inspection during production not to release any problem during production.

2: 100% UT inspection on each finished products.

3: Customer's own inspection.

4: Third party inspection.

5: UT( Ultrasonic Testing), MT, Spectrometer, Tensile strength, Impact test machine, Hardness tester

Packing method:wooden case for Free Fumigate or According to Customer,

Superiority

1. We had already passed the authentification by the ISO9001-2008, and established a completed set of quality assurance system.

2. Under such a complete set of quality assurance systems, there is a complete set of regulations for ordering, order handling, quality design, purchasing raw materials, working out production plan, production, test and inspection, packaging, storage, delivering, etc.

3. We also have a complete set of equipment and techniques for testing and controlling the performance of the forging products, which ensures our product quality to take a leading position among the products in domestic market and reach the international standard.

Product Categories : Types of Forging > Forged Ring